Technics 1200 socket with screws + tabs

Technics 1200 arm socket

It is with pleasure that Audiosilente introduces the new version of the technics 1200 arm socket, made of Avional Aluminum.

This version of the socket is fixed with 2 screws + expanding the tabs

This is a professional socket.

The improvements over the previous version are:

1 the inner thickness of the socket has been increased in order to allow the threads of the 2 screws a tighter grip

2 the knurling pattern now faithfully respects that of the original.

However, we have gone further: given that the Technics socket is attached to the arm tube by 2 screws and the interference usually found between the tube bore and the connector itself is about 0.05 mm - 0.04 mm, in our connectors this measurement has been reduced to 0.03 mm making it as accurate as possible to the barrel. Since there are obviously manufacturing tolerances of both the barrel and the connector, it is not possible to reduce the interference to 0 mm relative to the barrel, so drawing inspiration from the Sme connectors that we have already been manufacturing for a long time, we made a milling on the side opposite the screws. In this way, by expanding the connector tabs with a flat screwdriver at will, it is possible to press the connector itself into the barrel tube.

This type of connection allows the best coupling that can be made between connector and barrel. This provides maximum rigidity between connector barrel and headshell.

The customer can then decide to mount the connector securing it only by the screws without expanding the tabs as in the original model, or alternatively, the connector tabs can be expanded, making it possible to slightly adjust the azimuth of the headshell, thanks to the tight tolerance between barrel and screw holes(provided that the screws under the connector are left slightly loose). Another solution is to expand the tabs and tighten the screws, as usual.

Other features of the Audiosilente connector are as follows:

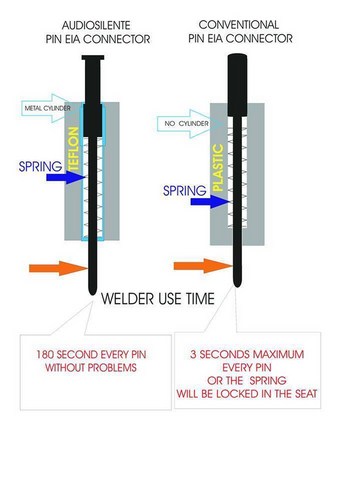

The inner insulating part is made of Teflon, which is a high temperature resistant and durable material.

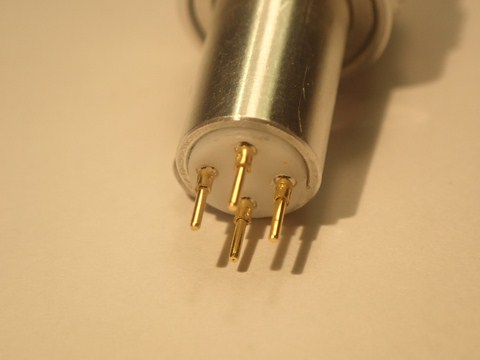

The spring pins are designed to Audiosilente specifications for a duty cycle of at least 30,000 movements.

The pins, made of gold-plated brass, are wrapped in a metal jacket in which they slide together with the spring, so the conduction of the music signal occurs with direct contact between connector pins and headshell pins (as opposed to some commercial products where the signal is carried by the spring).

All parts are cnc machined, including the pin holes, which are milledindividually.

Assembly of the pins, all parts that make up the connector, and testing are done manually one by one. This is the only way to be sure that each connector meets Audiosilente standards.

PLEASE NOTE THAT IN OUR CONNECTORS IT IS POSSIBLE TO SOLDER WIRES ONLY, IT IS NOT POSSIBLE TO USE CLIPS. ON REQUEST IT IS POSSIBLE TO SUPPLY THE CONNECTOR WITH EXCELLENT QUALITY WIRES ALREADY SOLDERED.

THE CONNECTOR IS SUPPLIED WITH UNEXPANDED TABS

Designed and manufactured in Italy by Audiosilente.

Due to the small section of the pins it is in fact impossible to use clips.