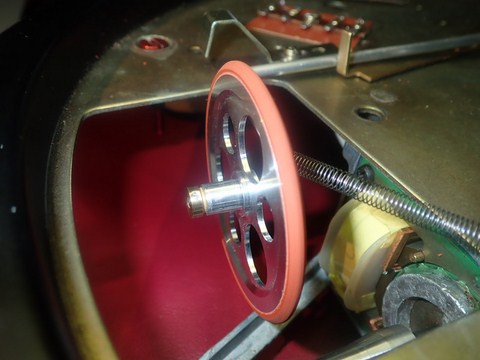

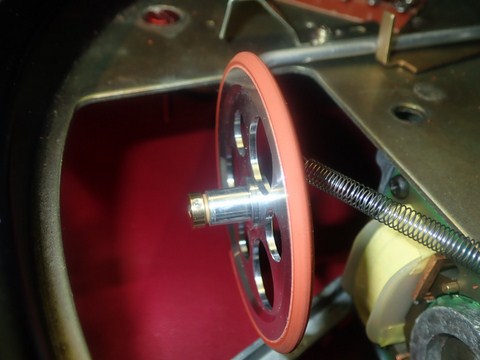

V shaped o-ring Lenco idler wheel (for 2.50 mm shaft)

New Lenco V Line silicone idler wheel with sintered bronze bushings.

This model is identified by the presence of an e-clip that locks the wheel on its shaft. Please verify the correct model before purchase

Through the use of an oversized silicone o-ring bonded to the wheel, the ultimate expression of the V line idlerwheels is achieved by grinding in order to obtain a wheel based on the same original Lenco profile BUT for the first time made out of silicone!

Each idler wheel is machined on a lathe for perfect roundness. In addition, individual testing of each wheel is performed to make sure they meet our parameters for the sale.

Once the lifecycle of the o-ring is over, after many years, it will be possible to replace the o-ring with a standard round o-ring also supplied. Until then the ground o-ring that comes glued to the wheel and ground for perfect roundness cannot be removed.

The kit includes 4 o-rings in all.

1 o-ring made of XXL oversized silicone to Audiosilente specifications, glued and V-ground

1 o-ring made of rubber with the same features as that of the original lenco idlerwheel

1 o-ring made of liquid silicone with oversized section

1 o-ring made of liquid silicone with reduced section

idler wheel Material :

CNC machined from Avional aluminum,

The weight of the idler wheel is only 17 grams. 2 grams more than the original version. The weight is critical because Lenco designed a suspended idler wheel so the interaction between idler wheel weight and spring type determines the amount of noise produced by the idler wheel itself and the turntable. A heavier wheel requires a new, higher tension, spring to exert an even grip on the platter and this causes more noise and more vibrations.

The new idlerwheel now mounts 4 sintered bushings, while the original Lenco wheel mounted only 2.

This idler wheel is the only one on the market that adopts this type of bronze.

Sintered bushings are made by hot pressing a mixture of bronze powders into a mold. At the end of the process the bushings are pre-impregnated with turbine oil. When examined under a microscope they show a highly porous structure within which the oil is contained.

Sintered bronze bushings thus represent the best material for rotating objects as the they release oil that creates a film around the shaft enabling the smooth rotation of the wheel.

Another special feature of sintered bronze is its high durability compared to other types of bronze and materials.

With sintered bronze, there is no risk of seized moving parts.

This is why all turntables, from Lenco to Garrard, including Thorens, have always used only sintered bronze.

The idler wheel is bored at 2,500 mm or 3,000 mm depending on the Lenco model required with reamers made to Audiosilente specifications

The process of making and assembling and centering bushings is very complex, but Audiosilente is always looking for more and more advanced products.

The gap that is created inside the wheel hole, between the bushings, allows you to put 1 drop of oil, so the bushings are always lubricated, just repeat the process 1 time a year and you will have a very durable wheel , without wear of the bushings.

It is recommended to use only synthetic oil with viscosity 0-20 W.